When you produce egg trays, those trays need to be dried. While there are a number of methods to dry these trays, you’ll get better results if you invest in a high-quality egg tray dryer machine. These are some of the things you should remember as you explore your various options.

Egg Tray Metal Dryer Shipped to Colombia

A System Will Play an Important Role In Your Manufacturing Plan

If you’re putting together a manufacturing plan for an egg tray plant, you’ll want to take every step of the process into consideration. That’s why you need to ask yourself a number of questions and focus on finding a system that is in line with your unique needs.

Some of the factors you’ll need to consider include the number of trays you’ll be producing per hour and the weather conditions in the area around your plant. With a high-quality system, you’ll be able to smoothly produce plenty of egg cartons. Besides, you can change the egg tray mould.

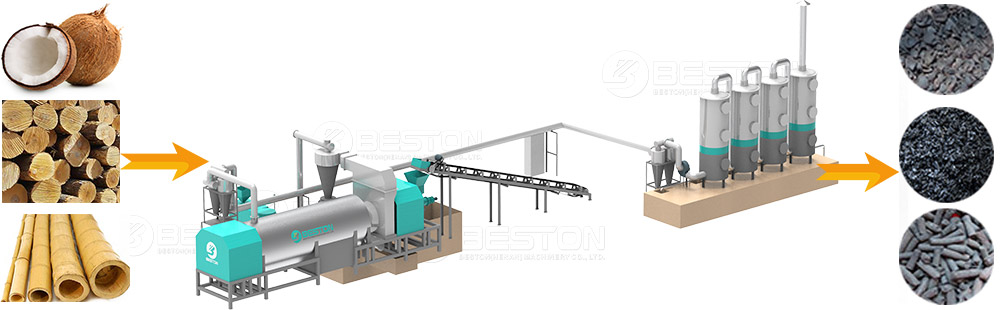

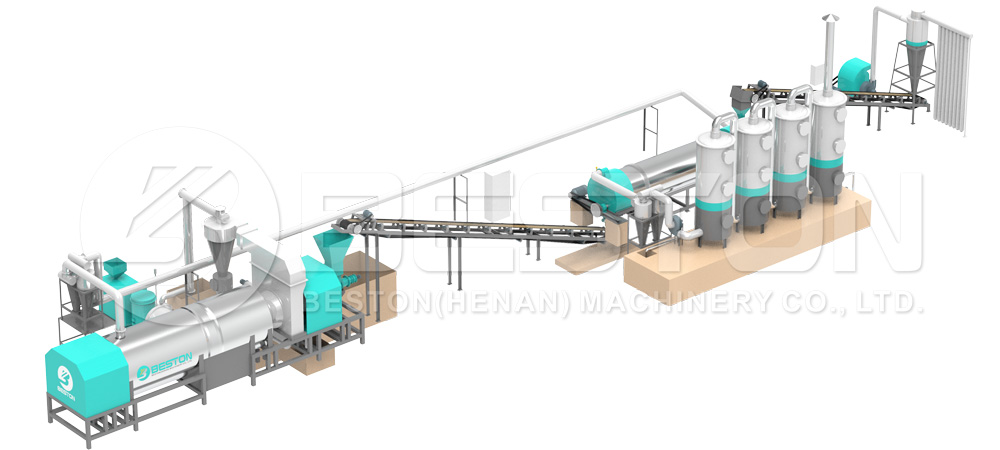

There Are Many Systems to Choose From

If you do decide to invest in an egg tray drying system, you’ll have an assortment of options to choose from. Natural drying systems are a popular option, as are automatic metal dryers and brick drying line.

The system that you select will impact many factors, including the total cost of your drying system and the equipment that you need. For a natural system, you’ll need a drying rack and cart, but for an automatic system, you’ll need to invest in more equipment. Having access to so many different options will give you the opportunity to select something that’s a good fit for you.

It Can Be Inexpensive

Although having access to the right drying system can make it easier for you to produce and sell egg trays, this doesn’t have to be an expensive purchase. Depending on the type of egg tray manufacturing unit you select, this could actually be a cost-effective investment.

You’ll have a range of choices available, which will allow you to find a solution that’s well within your budget. You can decide what you’re willing to invest, and from there, you can focus on the options that are comfortably in that range.

Beston Egg Tray Making Machine with Metal Dryer in the Philippines

There Are Suitable Options for Any Facilities

If you have a smaller manufacturing facility, you may not have much space for egg tray drying equipment. Thankfully, if you choose to invest in a drying system, you’ll be able to find plenty of small options that are well-suited to cramped spaces.

Of course, if you produce large amounts of egg trays, you’ll want to make sure that you’re able to dry all of the trays that you’re making as quickly as possible. You can find systems with a capacity of 6,000 or more. No matter how many egg trays you produce per hour, you’ll be able to find an appropriate solution on this page https://bestoneggtraymachine.com/pulp-molding-machine/.

Make sure that you invest in a high-quality egg tray dryer system. No matter what you ultimately decide on, you’ll want to review your options and make the best decision for your manufacturing facility. Find a system made by a trusted brand like Beston so that you’ll get better results.