In the ever-evolving landscape of sustainable technologies, tyre pyrolysis emerges as a beacon of innovation, promising not only environmental benefits but also a tapestry of economic advantages. To comprehend where the economic boon of tyre pyrolysis originates, one must delve into the intricate web of its processes and applications.

Unraveling the Essence of Tyre Pyrolysis

Tyre pyrolysis, at its core, is a thermal degradation process that transforms end-of-life tires into valuable resources, such as carbon black, oil, and steel. This intricate dance of heat and chemistry unlocks a spectrum of economic opportunities that extend far beyond the mere act of recycling.

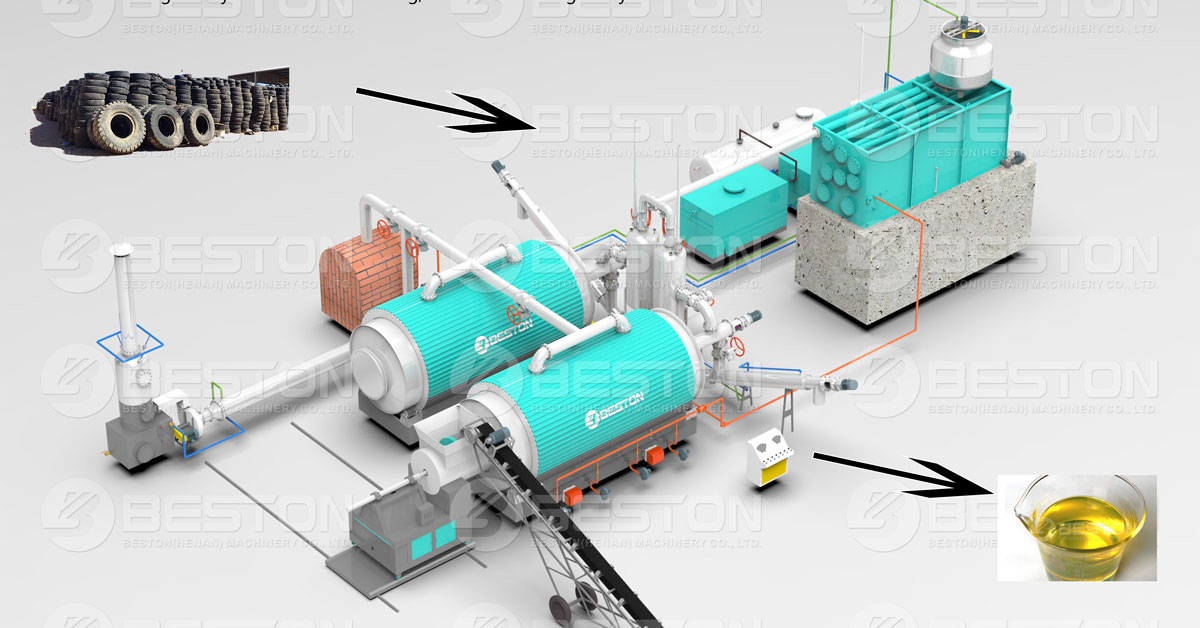

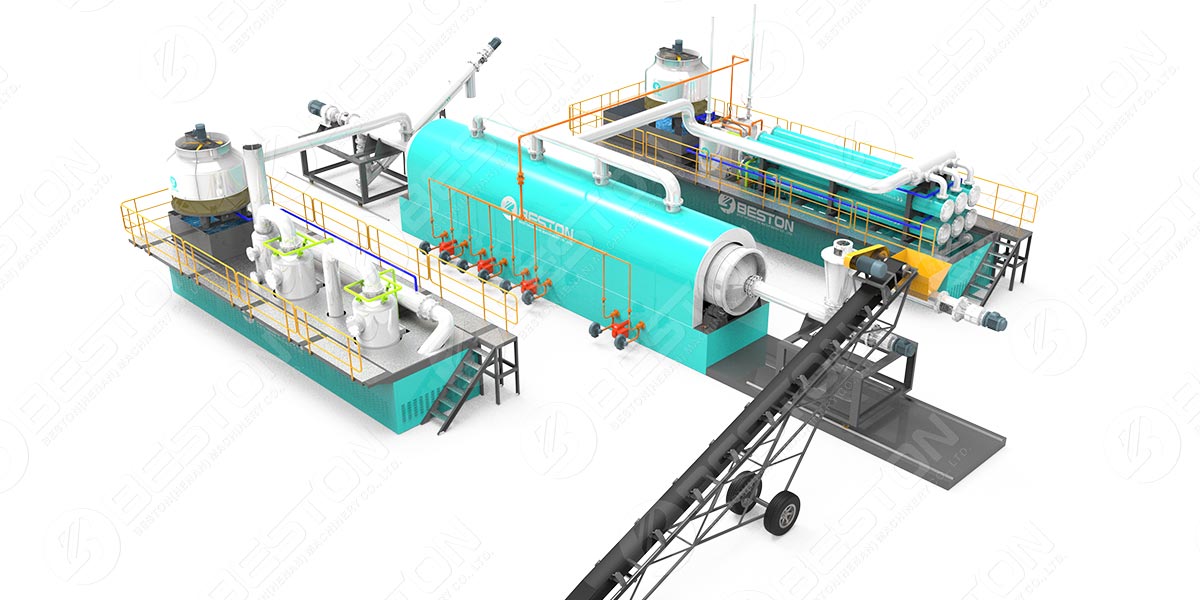

The tyre pyrolysis process of a tyre pyrolysis machine begins with the introduction of scrap tires into a high-temperature reactor. This controlled environment induces a thermochemical reaction, causing the rubber compounds to decompose into various components. Among the treasures unearthed are carbon black, a versatile material with applications spanning from the rubber industry to ink production, and pyrolysis oil, a rich source of energy.

Carbon Black: A Versatile Jewel

In the realm of economic benefits, carbon black stands as a multifaceted jewel. Its integration into the manufacturing of tires not only bolsters the quality and durability of new rubber products but also mitigates the reliance on traditional carbon black production methods, which often entail a hefty environmental footprint.

Igniting Energy Resilience with Pyrolysis Oil

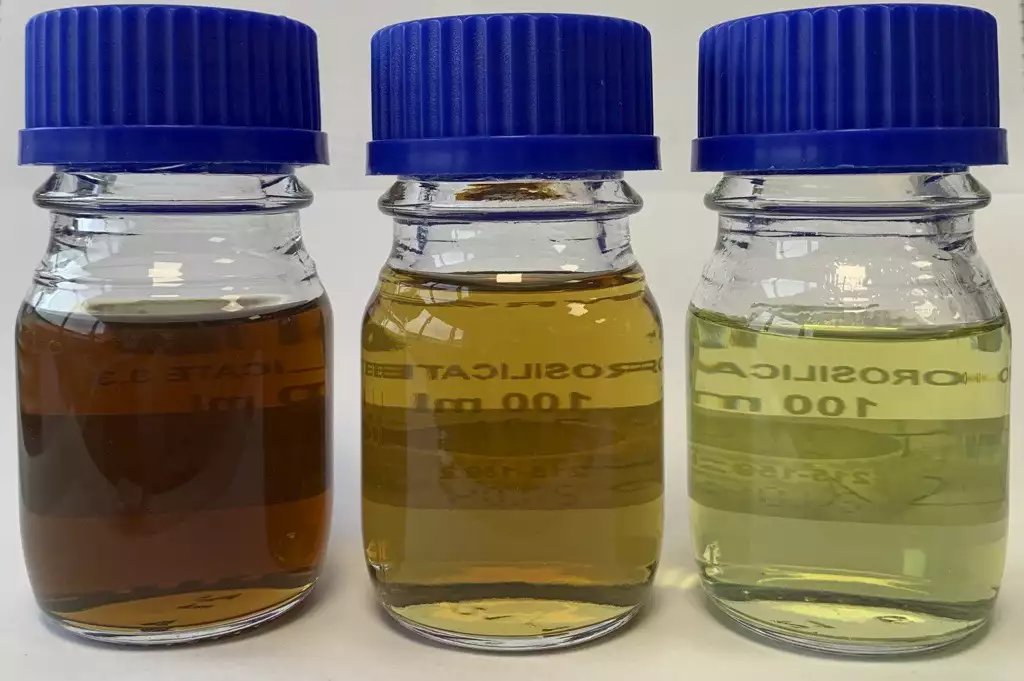

The economic landscape of tyre pyrolysis plant gains further dimension with the extraction of pyrolysis oil. This liquid gold, composed of hydrocarbons derived from the breakdown of tire polymers, can serve as a potent energy source. As industries increasingly pivot toward sustainable practices, pyrolysis oil becomes a compelling alternative to conventional fossil fuels.

Navigating the Economic Terrain

- Market Dynamics and Demand

The economic trajectory of tyre pyrolysis intertwines with market dynamics and demand patterns. As environmental consciousness permeates consumer choices, the demand for sustainable practices propels the market for tyre pyrolysis products. This burgeoning demand acts as a catalyst for economic growth, stimulating investments in technology and infrastructure.

- Carbon Black Market Surge

Within the sprawling landscape of the carbon black market, the influx of sustainably produced carbon black from tyre pyrolysis amplifies competition. This not only diversifies the market but also fosters an environment where eco-friendly practices become synonymous with economic prudence.

Economic Empowerment at the Local Level

Beyond the macroeconomic currents, tyre pyrolysis brings about a wave of economic empowerment at the local level. The establishment of tyre pyrolysis plants creates job opportunities, injecting vitality into communities. This decentralized economic model contributes to the resilience of local economies, fostering a symbiotic relationship between environmental stewardship and financial well-being.

Challenges and Opportunities on the Horizon

- Regulatory Landscape

While the economic benefits of tyre pyrolysis plant (also called tyre to oil plant) are undeniable, the landscape is not devoid of challenges. Regulatory frameworks play a pivotal role in shaping the economic viability of these ventures. Striking a balance between encouraging innovation and ensuring environmental safeguards is a delicate dance that policymakers must perform.

- Technological Advancements as Economic Catalysts

The canvas of tyre pyrolysis economic benefits expands with each stride in technological innovation. Advancements in reactor design, process efficiency, and product refinement amplify the economic yield of each tire subjected to pyrolysis. The synergy between technological prowess and economic prosperity underscores the transformative potential of this sustainable solution.

Where Prosperity and Sustainability Converge

In the grand tapestry of sustainable technologies, tyre pyrolysis emerges not just as a solution to the environmental quandary posed by end-of-life tires but as a dynamic engine propelling economic prosperity. The economic benefits of tyre pyrolysis, woven intricately into market dynamics, local empowerment, and technological advancements, paint a vivid picture of a future where the pursuit of sustainability and economic well-being converges seamlessly. As we navigate this path, it becomes increasingly evident that the economic roots of tyre pyrolysis run deep, branching out into a landscape where prosperity and sustainability intertwine in harmonious coexistence. You can search Beston Group to know more information about batch and continuous pyrolysis plant.