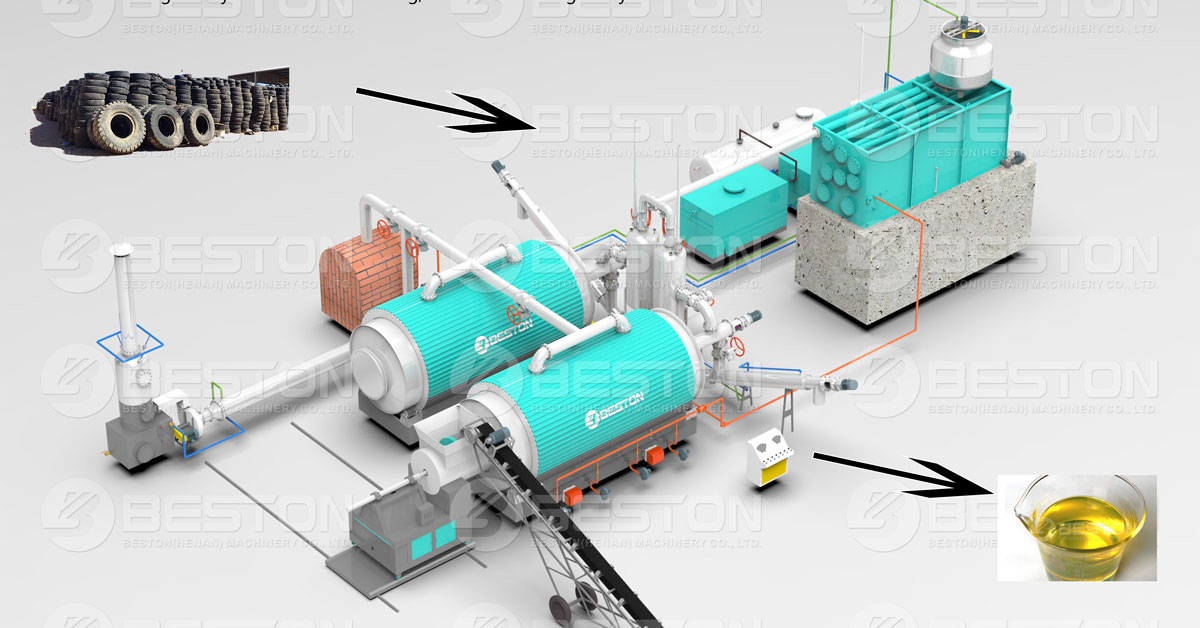

Are you looking for a continuous pyrolysis machine for sale? If so, you have come to the right place. A continuous pyrolysis machine is a great solution for reducing the number of waste tires that collect in landfills across the globe. With the number of vehicles increasing around the world, waste tire disposal has become a huge problem.

Dumping waste tires in landfills is not the best solution. It affects the environment in a negative way since waste tires and other plastic waste don’t decompose quickly. They take hundreds of years to decompose and create numerous environmental issues over time. That’s why continuous pyrolysis technology (planta de pirolisis de lodo aceitoso) is becoming so popular around the world. Investing in a continuous tire pyrolysis machine is a great way to protect your ecosystem while earning a handsome profit in the process. This article provides information on why you should invest in a high-quality continuous tire pyrolysis plant for sale.

Planta de Reciclaje de Neumáticos en Chile

Pyrolysis plants are available in two major types such as the batch pyrolysis plant (planta de pirólisis continua) and the continuous pyrolysis plant. The former needs a lot of labor to operate because of its low automation. The batch-type machine is not that efficient since it has to be stopped for several hours after each batch of tires or plastic waste is processed. You have to remove the remnants from the chamber of the machine after each batch is processed. In fact, feeding tires into the machine is not continuous since the plant has to be halted after processing one batch of tire or plastic waste. That’s why you should invest in a continuous tire pyrolysis machine to recycle more tire and plastic waste and earn better profits in the long run.

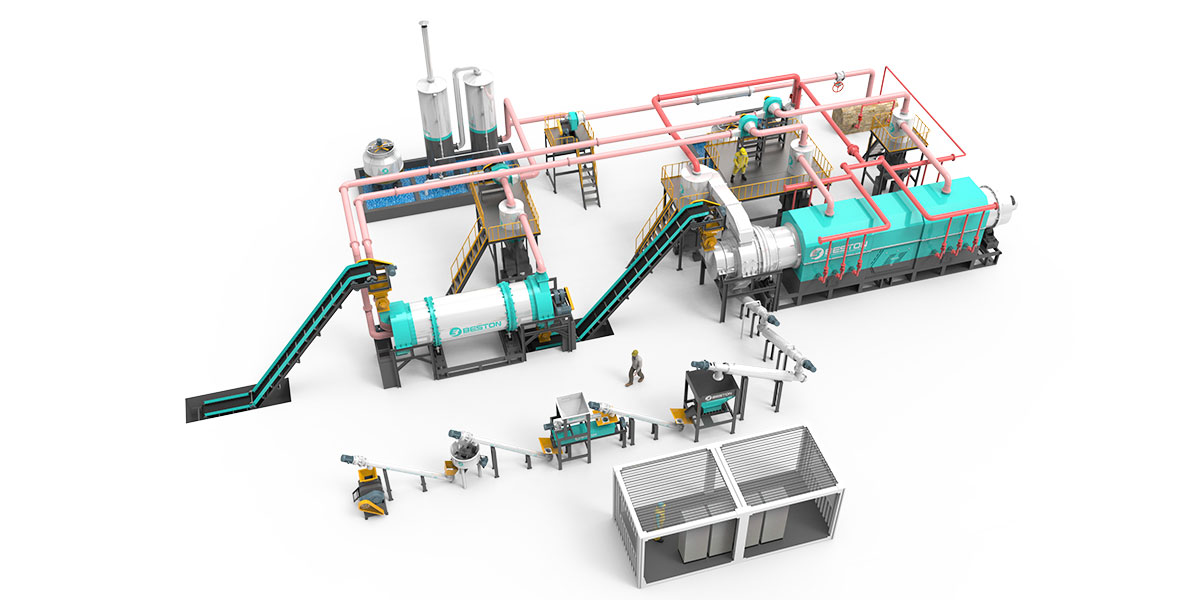

One of the most appealing benefits of a continuous plant is its huge processing capacity. There are different capacities to choose from depending on your business needs. Since waste tires are available almost everywhere, you can definitely invest in a high-capacity machine if you have the capital to do so. In a nutshell, a continuous plant should operate 24-7 for many weeks at a stretch. You only need to feed a consistent volume of waste tires and the chamber will keep on converting them into various profitable products.

When you are shopping for a continuous pyrolysis machine (https://www.bestoneco.com/blj-16-planta-de-pirolisis-de-neumaticos-enviado-a-chile/) on the market, you may find countless manufacturers. But not all of them are top-notch or trustworthy. You should be doing extensive research to find a reliable manufacturer or supplier of high-quality continuous pyrolysis plants on the market. Make sure you invest in a machine that has the latest technological features. The more automation features the machine has, the better your profit potential is.

Overall, there are many advantages to choosing a continuous tire pyrolysis machine for your business. You can care for the environment and make a handsome profit at the same time with a high-quality pyrolysis machine for sale. The aforementioned article provides important information on why you should invest in a continuous tire pyrolysis plant for sale for your business (Beston Group China).