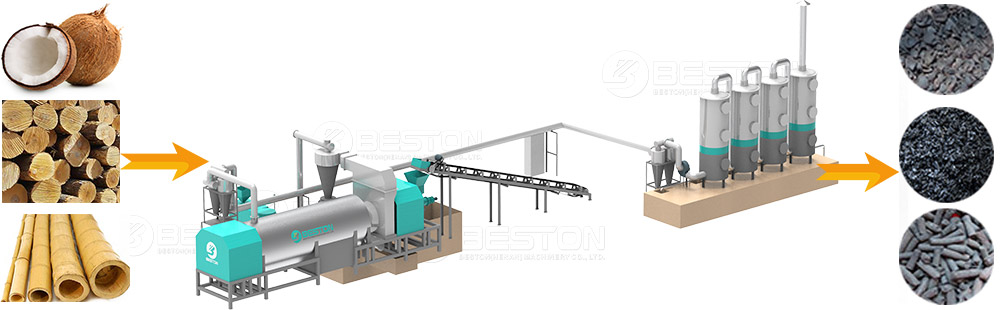

When it’s time to buy a sawdust charcoal making machine, you’re going to have a few to choose from. It’s a good plan to know what you’re in for before you start your search. That way, you can avoid spending money on something you may not benefit from all that much.

Get a good look at a sawdust charcoal making machine that you’re interested in before you spend anything. You want to know if it’s in good shape and it’s smart to get a feel for what the size of it is. You don’t want to buy something without knowing what you’re getting because then you could get stuck with a machine that you don’t really like when you finally get to check it out. If you can’t go check on it in person before making a purchase, ask the seller if they can send you a few photographs of what you’re interested in.

It’s never a good idea to spend your money on a machine that is overpriced. Sometimes, there are companies that try to take advantage of buyers because they know that sometimes there are people out there that know no better when it comes to what a sawdust charcoal type of machine is worth. You don’t have to look hard to find out what a few companies want people to pay for what they have. Once you get a good look at biomass pyrolysis plant costs across a few sellers, you don’t have to worry about overpaying for anything.

Pick a machine that is known to be of higher quality than the cheaper options. Even if you can save money by getting something different, if it’s of low quality then it’s generally not a good pick. If something isn’t made well, it can break down on you quickly which means you’ll have to pay to fix or replace it. If you do the math, you’ll see that it’s actually cheaper to go with something that’s made well in the first place. If you’re wondering what a machine’s quality level is like, seek out reviews that can let you know. Here are more solutions: bestonasia.com.

Never try to do a repair when you get a machine if you’re not sure of what you are doing. You’re going to find that sometimes, there are issues that just shouldn’t be worked on by an amateur. There probably is a mechanic out there that you can get a hold of that you can let look over everything and then do their work to get it all back up and running. At the very least, read up on what to do and then you can have detailed knowledge about what you’re doing instead of just trying to guess at what to do.