Charcoal has been used as a fuel source for centuries, but it’s only recently that we’ve begun to fully understand the potential of this material. Charcoal is an excellent source of carbon, which can be used to create a range of products, from fertilizer to high-performance batteries. However, traditional charcoal production methods are often inefficient and produce harmful emissions. Get the biochar maker for sale from reliable manufacturers.

Continuous Biochar Machine for Sale Shipped to Mexio

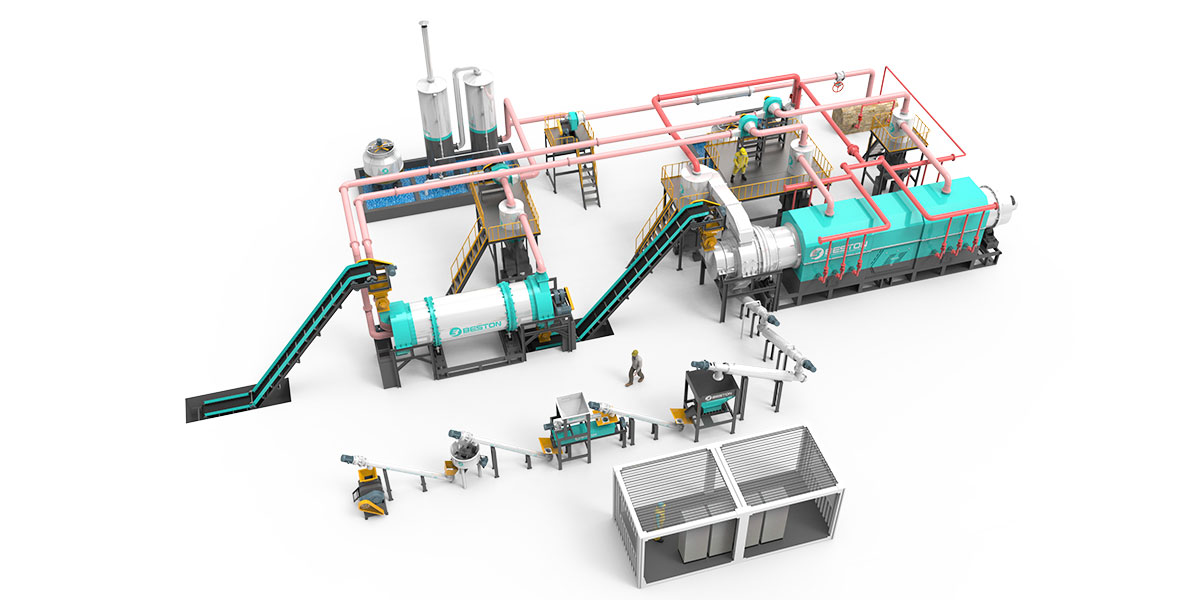

Biochar makers are a new technology that could revolutionize the way we produce charcoal. These devices allow for the creation of biochar, a type of charcoal that is produced through a process called pyrolysis. Unlike traditional charcoal production methods, pyrolysis doesn’t produce harmful emissions, and it’s a much more efficient process.

The biochar maker for sale in the global world is an excellent opportunity for individuals and businesses to unlock the potential of charcoal production. By investing in a biochar maker, you can create a range of valuable products that can be sold for a profit. Additionally, biochar production has a range of environmental benefits, including reducing greenhouse gas emissions and improving soil health. This type is a good option for your recycling business: https://bestonmachinery.com/charcoal-making-machine/continuous/.

Biochar Machine Shipped to Malaysia

One of the most exciting applications of biochar is in agriculture. When biochar is added to soil, it improves soil health and can increase crop yields. Additionally, biochar can sequester carbon in the soil, reducing greenhouse gas emissions. This makes biochar an excellent tool for sustainable agriculture.

Biochar can also be used as a filter material in a range of applications. For example, it can be used to filter water or air, reducing the level of pollutants and contaminants. Additionally, biochar can be used as a high-performance battery material, allowing for the creation of long-lasting and efficient energy storage systems.