In the realm of renewable energy, biomass pyrolysis stands out as a promising avenue for generating heat and power while mitigating environmental impact. By harnessing the transformative potential of organic matter, this innovative process offers a sustainable alternative to traditional energy sources. In this article, we delve into the intricacies of biomass pyrolysis and its role in the quest for a greener, more resilient energy future.

Role of Charcoal Machine in Biomass Pyrolysis

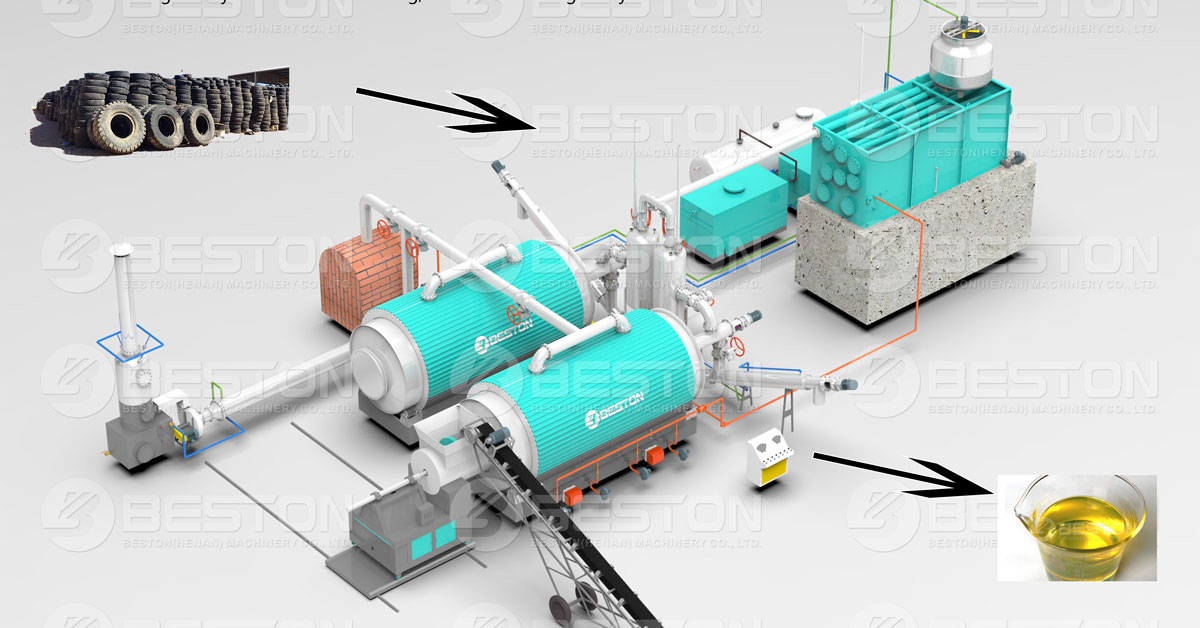

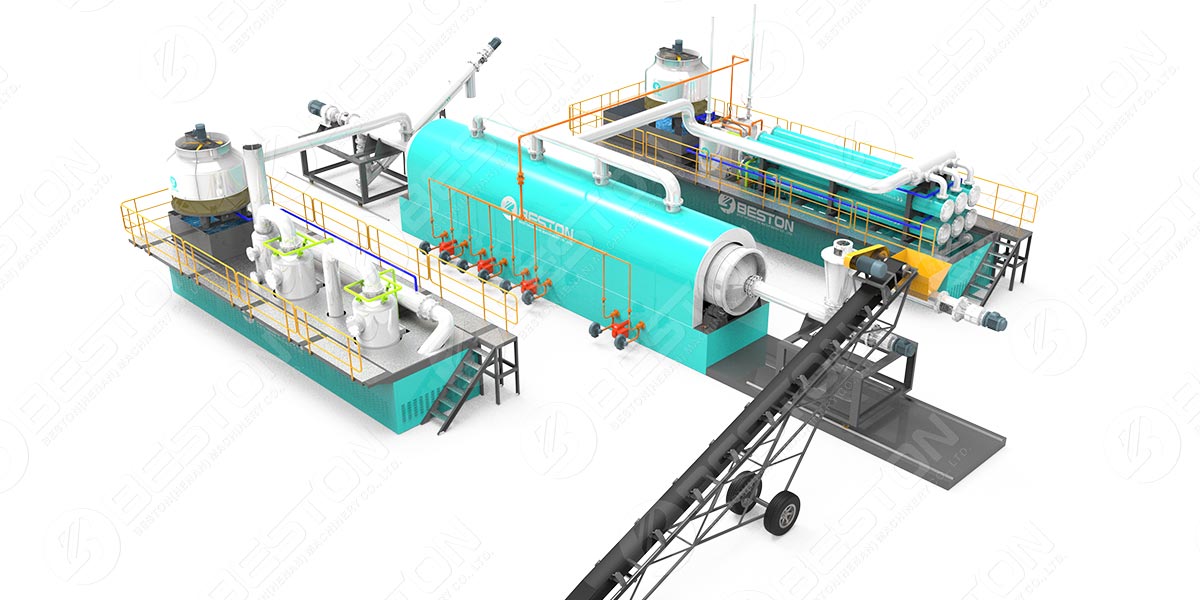

Central to the success of biomass pyrolysis is the charcoal production machine, a sophisticated apparatus designed to facilitate the controlled thermal decomposition of biomass feedstock. Equipped with precise temperature controls, efficient heat transfer mechanisms, and advanced gas handling systems, charcoal machines enable the optimization of pyrolysis processes for maximum yield and energy efficiency. From small-scale units suitable for community-based initiatives to industrial-scale installations powering grid-connected operations, charcoal machines play a pivotal role in unlocking the potential of biomass as a renewable energy resource.

Role of Biochar

One of the key outputs of biomass pyrolysis is biochar, a carbon-rich material with myriad applications in agriculture, environmental remediation, and carbon sequestration. Biochar serves as a potent soil amendment, enhancing fertility, water retention, and nutrient uptake in agricultural settings. Moreover, its porous structure provides a habitat for beneficial microorganisms, fostering soil health and resilience. Beyond agriculture, biochar holds promise as a tool for carbon capture and storage, offering a pathway towards mitigating climate change.

Environmental Benefits of Biomass Pyrolysis

Beyond its direct contributions to renewable energy generation, biomass carbonizer machine offers a host of environmental benefits. This process reduces methane emissions and alleviates pressure on finite landfill space by diverting organic waste from landfills and incinerators. Furthermore, the production of biochar enhances soil carbon sequestration, mitigating the impacts of deforestation and land degradation. As a closed-loop system, biomass pyrolysis embodies the principles of circular economy, transforming waste streams into valuable resources while minimizing environmental footprint.

Economic Viability and Market Potential

In addition to its environmental and social benefits, biomass pyrolysis holds considerable economic potential. The scalability and versatility of pyrolysis technologies make them suitable for a wide range of applications, from decentralized energy production to industrial manufacturing processes. As governments and industries seek to transition towards renewable energy sources, the demand for biomass-derived products is expected to grow exponentially. Investments in biomass pyrolysis machine infrastructure offer attractive returns while contributing to job creation and economic development in rural communities.

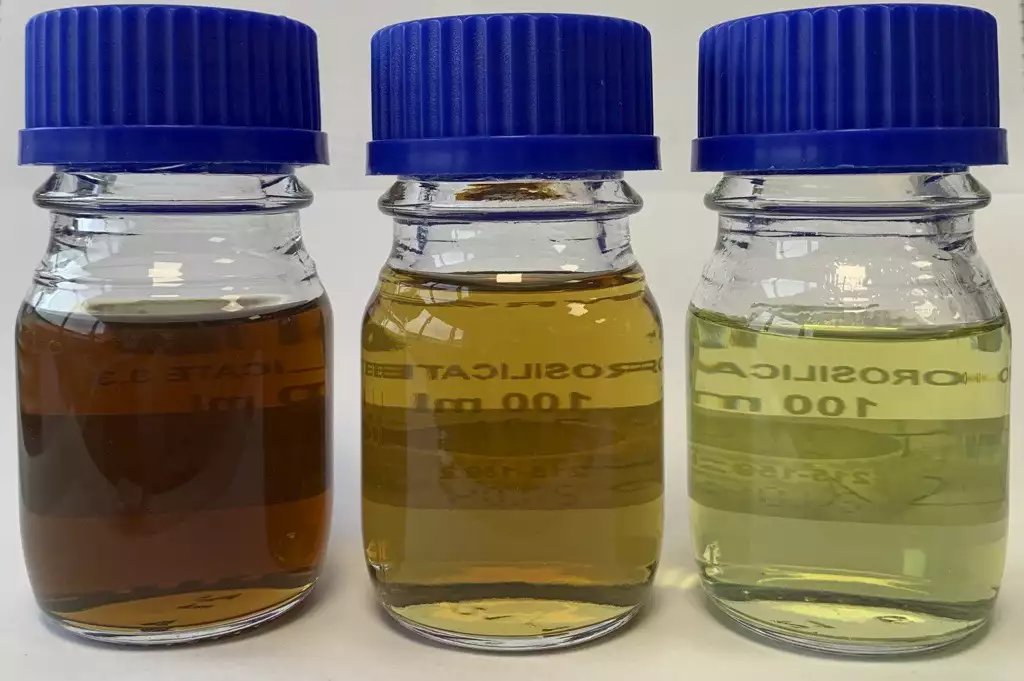

Biochar

Overcoming Challenges and Future Prospects

Despite its promise, biomass pyrolysis faces several challenges, including technological barriers, feedstock availability, and regulatory uncertainties. Continued research and development efforts are needed to optimize pyrolysis processes, improve efficiency, and reduce costs. Moreover, supportive policy frameworks and incentives are essential to incentivize investments in renewable energy technologies and facilitate market growth. With concerted efforts from governments, industries, and research institutions, biomass pyrolysis has the potential to emerge as a cornerstone of the transition towards a low-carbon economy.

Conclusion

In conclusion, biomass pyrolysis represents a sustainable solution for renewable heat and power generation. By harnessing the energy potential of organic waste streams, this innovative process offers a pathway towards mitigating climate change, enhancing soil health, and promoting economic development. From biochar soil amendments to bio-oil fuels and syngas energy carriers, the diverse outputs of biomass pyrolysis hold promise for a greener, more resilient future. With continued advancements in technology and supportive policy frameworks, biomass pyrolysis has the potential to play a significant role in shaping the global energy landscape for generations to come. Welcome to visit Beston Group to consult wood/coconut shell/rice husk/straw/shisha charcoal making machine!