If you are looking to get a tire pyrolysis system(planta pirolisis llantas), there are a few important aspects to keep in mind to ensure you make the right decision. The tire recycling business might be lucrative, but it comes with its fair share of challenges. It’s an eco-friendly business, but also one with harsh competition. At the end of the day, your venture’s profitability will depend on the technology you pick for your pyrolysis system.

Máquina de trituradora

Simply said, it would not be wrong that it’s in a sense, a technology business as the process’ efficiency goes a long way in determining the yield of the final products. So, without further ado, let us dive straight into what you need to know about purchasing a pyrolysis plant.

Technology Utilized

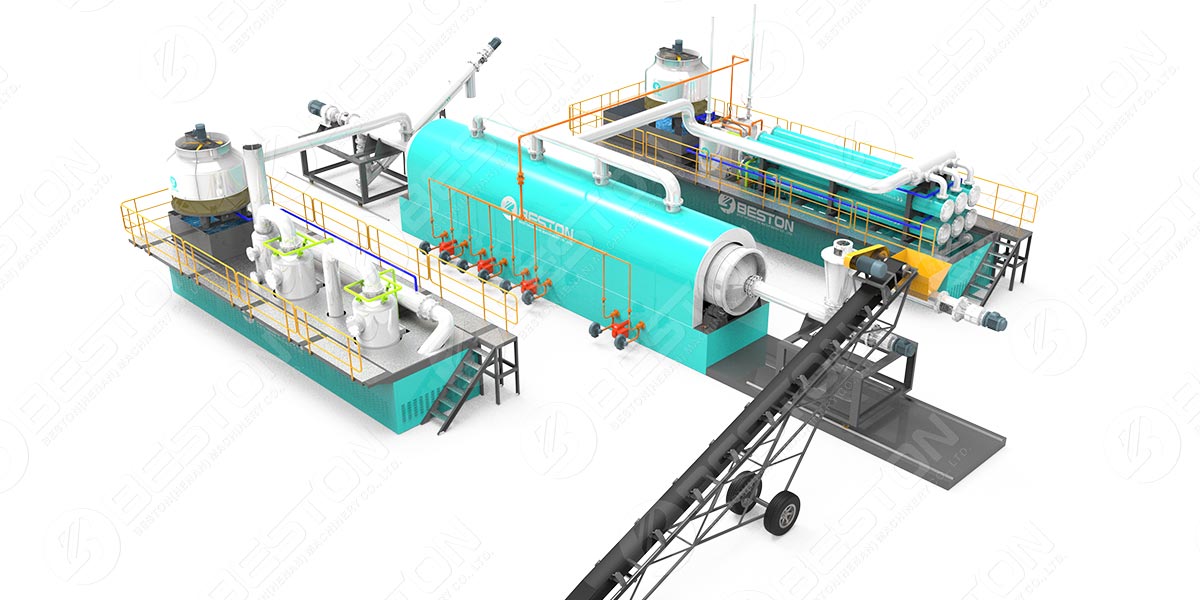

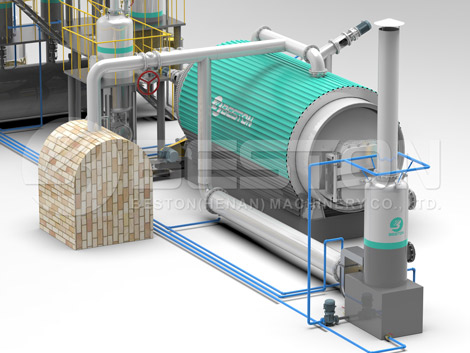

Although the pyrolysis(planta pirolisis neumaticos) principle stays the same, in all the machinery variations out there, it doesn’t imply that all plants are exactly the same in regard to design, efficiency as well as underlying technology. A lot of innovation and improvements have been made over the past several years, most notably the materials used to make the systems and the overall workflow.

Polvo de caucho

This has resulted in far way more energy-efficient plants as the energy being removed from some processes is harnessed in the recent designs and re-routed for other applications. Simply put, the yield from modern plants is way higher compared to older systems, and that additional yield goes a long way in making more profits for a business. As such, you’ll want to first consider the underlying technology utilized in a pyrolysis plant before making the final decision.

The Plant’s Capacity

A pyrolysis plant’s capacity will play a vital role in the yield you can derive from the system(https://www.bestoneco.com/planta-de-reciclaje-de-neumaticos/). Those without much experience in this industry tend to make the mistake of purchasing as much capacity as possible without paying close attention to the relationship between efficiency and capacity. If you purchase a high-capacity system but are unable to use it to its full potential, then the process won’t be as efficient and you will only have wasted money. That’s why it is imperative to pay close attention to the capacity and whether you can hit a 100 percent utilization rate.

The Business Plan

If you intend to purchase a pyrolysis machine without an ideal business plan(ECO Beston), then you’re only setting yourself up for failure or poor investment. No matter the size of your business, it is imperative to have a solid plan in place. It should entail the costs for setting up the system and the money you will be able to make from the sales of the products derived from the plant. Also, it should include the approvals you’ll need from the local government, availability and the logistics of both raw materials and finished products, availability of water, availability of labor, availability of power, and the like. Simply put, you should have a business plan in place before you begin shopping for the machinery.