The accumulation of end-of-life tires poses a persistent threat to ecosystems and urban infrastructure. Characterized by their resistance to degradation and their bulk, discarded tires contribute significantly to landfill congestion, fire hazards, and vector-borne disease proliferation. Conventional disposal methods such as incineration and shredding offer limited recovery potential and often exacerbate environmental burdens. Pyrolysis, a thermochemical decomposition process conducted in an oxygen-deficient environment, has emerged as a scalable and resource-efficient solution to tire waste management.

Converting Waste into Value: The Pyrolysis Process

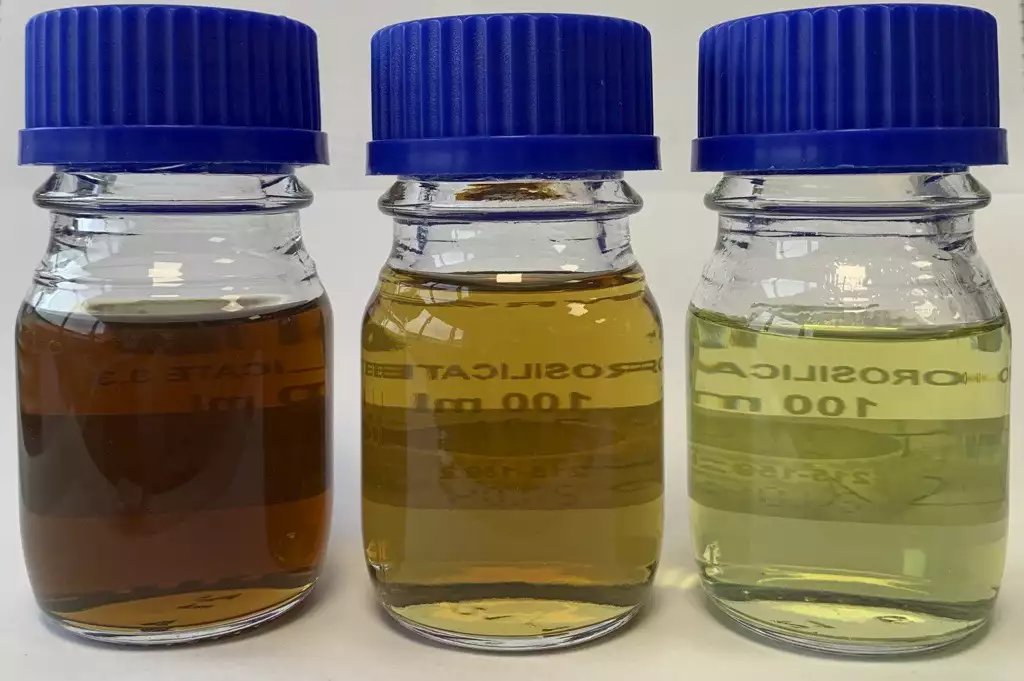

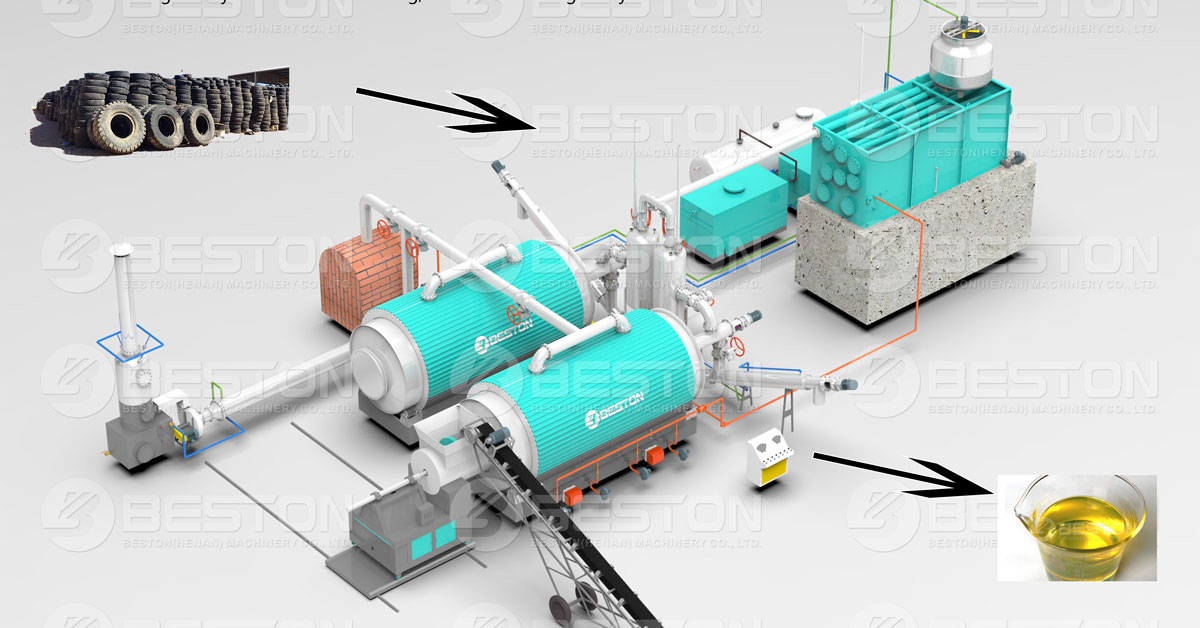

A waste tyre pyrolysis plant enables the controlled breakdown of rubber polymers into valuable byproducts. When fed into a pyrolysis reactor, shredded tire materials undergo thermal degradation at temperatures between 400°C and 500°C. In the absence of oxygen, volatile compounds are released and condensed into pyrolysis oil, while solid residues are recovered as carbon black and steel wire.

Pyrolysis oil is a combustible hydrocarbon liquid that can substitute for industrial heating fuels or be refined into transport-grade diesel. Carbon black, once reprocessed, can be used in pigment production, polymer reinforcement, or as a feedstock in asphalt modification. The steel recovered is recycled through traditional metallurgical channels.

Technological Advancements in Continuous Systems

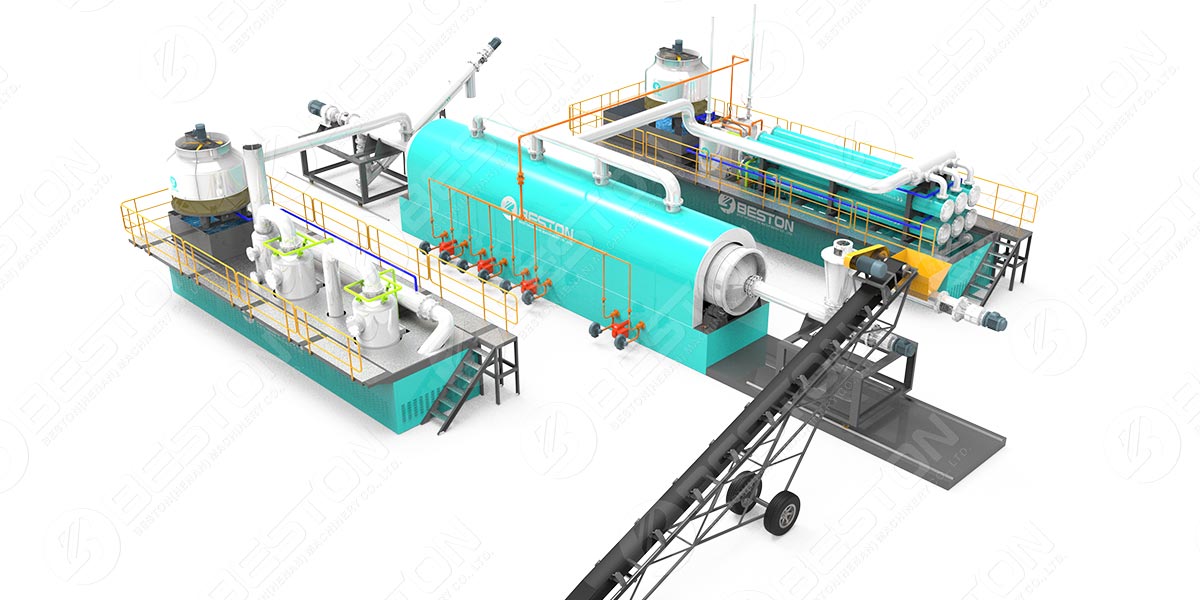

Traditional batch-type systems have given way to more sophisticated, high-throughput configurations. A continuous pyrolysis machine integrates feedstock handling, reactor operation, and residue discharge into a seamless process. The continuous input and output capability reduces thermal cycling, optimizes energy use, and minimizes labor requirements.

In a modern pyrolysis oil plant, automation and process control technologies ensure consistent output quality and enhanced operational safety. Real-time temperature and pressure monitoring systems within the pyrolysis reactor mitigate the risk of overheating and improve conversion efficiency. Some plants incorporate heat recovery units that utilize non-condensable gas to sustain reactor temperature, reducing reliance on external energy sources.

Environmental and Regulatory Considerations

Pyrolysis offers a comparatively low-emission alternative to open burning or landfilling. With proper gas scrubbing and condensate recovery systems, volatile organic compound emissions can be brought within regulatory limits. A well-designed waste tyre pyrolysis plant includes multi-stage filtration units to handle particulates, acid gases, and aerosols.

Many regions are implementing extended producer responsibility (EPR) frameworks that require tire manufacturers to account for end-of-life management. Pyrolysis systems can play a strategic role in meeting these obligations while generating marketable byproducts. When certified under carbon accounting protocols, the avoided emissions and resource recovery can be monetized through carbon credit markets.

Economic Viability and Market Dynamics

The value proposition of a pyrolysis oil plant lies in its ability to turn liability into revenue. The global demand for alternative fuels, especially in regions facing diesel shortages or fuel import dependency, creates a viable outlet for pyrolysis oil. Carbon black also finds steady demand in the manufacturing sector. Furthermore, the modular design of newer systems allows for decentralized deployment, enabling regional waste management authorities and private operators to establish processing hubs near the waste source.

Conclusion

Pyrolysis technology offers a technically sound and economically feasible approach to end-of-life tire disposal. With the integration of a continuous pyrolysis machine, robust pyrolysis reactor design, and comprehensive emissions control systems, a waste tyre pyrolysis plant can simultaneously address environmental mandates and generate industrial-grade commodities. As the circular economy gains momentum, pyrolysis stands as a cornerstone in sustainable material recovery from tire waste.