Do you need waste pyrolysis machine? Because if you do, there are a few things you’ll want to keep in mind. This article will go into details about where to find pyrolysis machine for sale and how you should go about choosing equipment. With that said, here’s what to keep in mind:

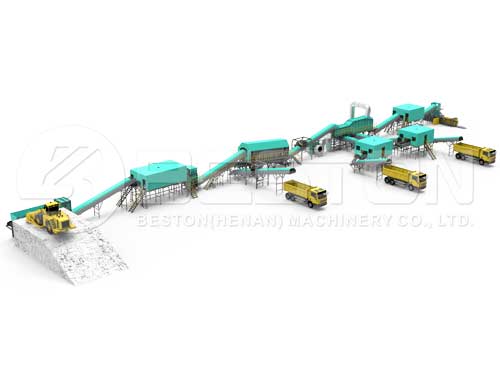

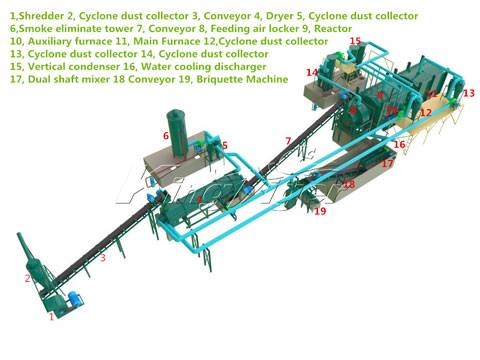

Beston Pyrolysis Plant with Good Parts

Where To Find Waste Pyrolysis Machine For Sale

There are third-party websites like Beston Machinery that sells all kinds of pyrolysis equipment. This includes rubber, sludge to oil and tires to name a few. There is also tire to oil pyrolysis equipment that can be found online. However, that site is not the only site that sells equipment, as there are many marketplaces on the internet that sells them too. There is a web for you to visit: https://bestonturkey.com/waste-tyre-recycling-plant/.

What you want to do is a search online for the equipment. Find at least 3-5 websites that sell it and then browse their selection of waste pyrolysis machine. Not all of them will sell the same type of equipment.

Used & New Waste Pyrolysis Machine

Used pyrolysis equipment is affordable and cost far less than new equipment. If buying used, you’ll want to inspect the equipment because sometimes used equipment can be in bad shape. As long as you purchase from a reputable seller, this shouldn’t be an issue.

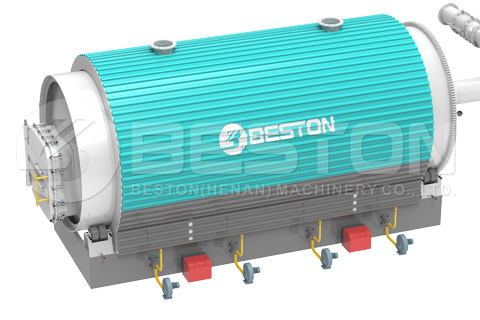

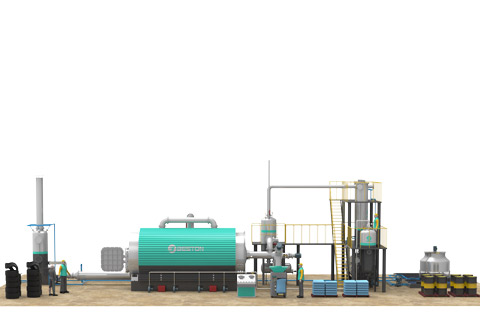

Beston Waste Pyrolysis Machine for Sale with Good Quality

New equipment may be more expensive, but it tends to last longer than used equipment. In the long run, you could end up saving money. Generally speaking, it’s a good idea to buy a new piece of equipment, especially if you plan on using the waste pyrolysis machine on a regular basis. If you’re only going to use it every now and then, go ahead and buy a used piece of equipment.

Read Reviews

What are real customer saying about the waste pyrolysis machine you’re thinking about buying? Is the equipment you’re looking at durable, reliable and do the features in the description do what they say they’re going to do? These are all a few things you’ll likely find out by reading reviews, but make sure you only read reviews on sites that verify their reviews. You want to make sure you’re reading legitimate reviews, otherwise you could end up wasting your money on equipment that either works very well, moderately well or not work that good at all.

Warranty

Finally, the pyrolysis equipment you buy should have a warranty. You want to find out what the warranty covers and whether or not you’ll have to pay anything before the warrant can be used. Different sellers have different warranties, and different machinery will have different manufacturer’s warranties, so it’s a good idea to learn what the warranties entail. Generally speaking, it’s a good idea to buy a machine that has both a manufacturer’s warranty and a warranty offered by the company selling it. Beston & Company guarantees the quality and service.