After deciding to buy egg tray making machine, do not rush to buy it. Look for the best egg tray making machine suppliers. However, choosing the best suppliers is not easy because there are so many suppliers to choose from.

If you have a problem choosing the right egg tray machine manufacturers, continue reading.

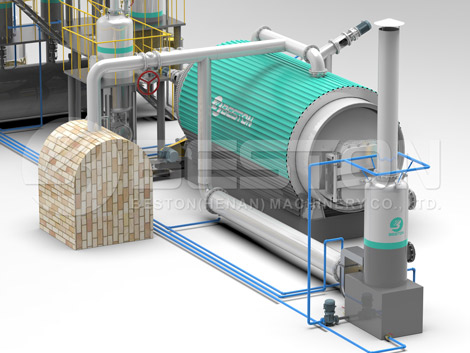

Beston-Reliable Egg Tray Making Machine Supplier

1. Check out their Website

Firstly, check the websites of different suppliers. Most suppliers have websites. They use their websites to build their brand.

In addition, the best suppliers use their websites to educate their potential customers. They share quality content on their websites.

Be careful when you find websites that contain promotional content only. If the supplier cannot take the time to create quality content, it means the supplier does not care about its customers. That is why you need to avoid these suppliers.

Choose a supplier that share quality content on their website.

2. Read their Customer Reviews

If you are doing your research, do not visit the websites of these suppliers only. There are other websites that have reviews of these suppliers. They have genuine reviews. The best manual egg tray making machine suppliers get good reviews because they sell authentic machines.

However, some suppliers get a lot of negative reviews. Why? Because they sell poor quality machines. Avoid suppliers that have a lot of negative reviews. These suppliers usually have a lot of complaints. Avoid them if you do not want to lose your hard earned money.

Choose a supplier that has good customer reviews.

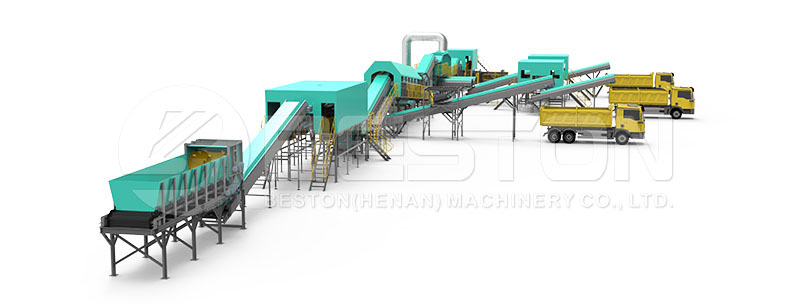

Egg Tray Making Machine in India

3. The Experience of the Supplier

You need to know how long the supplier has been in this industry. There are new suppliers. They do not have enough experience, so it is hard to know the quality of their machines. It is better to avoid them, especially if you are on a tight budget and you do not want to make mistakes.

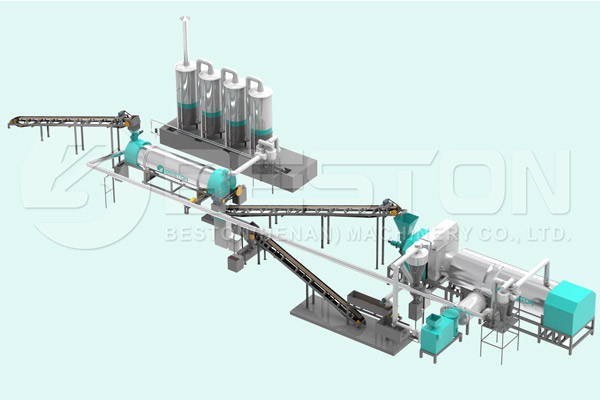

The best suppliers have several years of experience, so they have a proven track record. A lot of people have used these suppliers. When you talk to these suppliers, they will show you the machines they have sold. They also have an in-depth idea about the machines they are supplying. Usually, the egg tray making machine can also make egg boxes, egg cartons (https://www.bestongroup.com/egg-carton-making-machine/) and other paper trays, so you need to make sure if the suppliers really understand your needs.

Choose a supplier that has several years of experience.

4. The Reputation of the Supplier

This is where most people make mistakes. They have done their research. They have found a supplier that has several years of experience. However, they fail to check the reputation of the supplier. The best suppliers have a good reputation. A lot of people love these suppliers.

However, there are some suppliers that have a negative reputation. They sell low-quality egg tray making machines. In fact, they rarely get repeat customers. And they ignore their customers after they buy their machine. Avoid these suppliers.

Choose a supplier that has a good reputation.

You now know how to choose the best egg tray making machine suppliers. Look for suppliers that have several years of experience. Avoid suppliers you do not know or trust. If you do not know the reputation of a supplier, avoid that supplier. Stick with suppliers that have a good reputation.

Click here to learn more about the egg tray machine in india and the reliable suppliers of it.