Biochar, traditionally recognized for its agricultural applications, is now being harnessed as a renewable solid fuel in industrial and decentralized energy systems. With increasing demand for low-emission alternatives to coal and biomass, biochar presents a viable energy vector due to its high carbon content, low moisture, and excellent combustion properties. Modern carbonization facilities, equipped with advanced technology, have enhanced the consistency, yield, and calorific value of biochar derived from various lignocellulosic feedstocks.

Energy Potential of Biochar

The calorific value of biochar typically ranges between 25–30 MJ/kg, depending on feedstock and process parameters. Unlike raw biomass, biochar exhibits higher energy density, minimal off-gassing, and lower particulate emissions upon combustion. These traits make it suitable for co-firing in industrial boilers, gasifiers, and even small-scale cookstoves.

Biochar’s stable molecular structure, rich in aromatic carbon rings, ensures slow oxidation and prolonged energy release. As a result, it functions not only as a fuel source but also as a heat-retaining medium in kilns, smelters, and thermal treatment applications.

Feedstock Versatility and Machine Efficiency

Production facilities utilize a wide spectrum of agricultural residues. Rice husk, abundant in silica and often considered a low-grade waste, yields biochar with favorable ignition properties. A rice husk charcoal making machine is specifically engineered to manage the abrasive and lightweight nature of the husks, ensuring consistent carbonization through indirect heating and internal flue gas recirculation.

Similarly, palm kernel shell, a dense biomass byproduct from palm oil processing, produces high-quality charcoal with elevated fixed carbon and energy output. The palm kernel shell charcoal machine is designed to accommodate the hardness and oil content of the shells, often incorporating rotary reactors and temperature-controlled chambers to prevent tar formation.

More generalized systems, such as a carbonization machine, are configured to process a wide range of input types—from wood chips and coconut shells to corn cobs. These systems typically integrate gas cleaning units, combustion chambers, and auto-feeding systems to optimize throughput and minimize energy loss.

Integration of Heat Recovery and Emission Control

Modern charcoal making equipment goes beyond simple carbonization. Most systems are built with heat recovery features that capture and reuse pyrolysis gases to maintain reactor temperature, thereby reducing external fuel demand. The surplus heat can be repurposed for drying feedstock, steam generation, or auxiliary power production, enhancing overall energy efficiency.

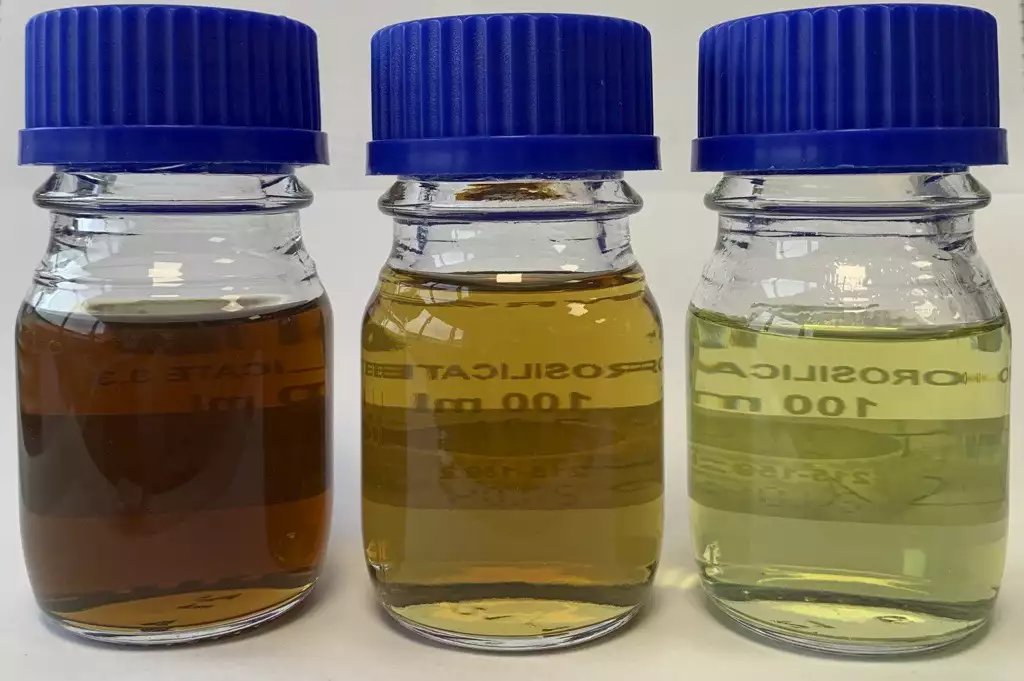

Emission control mechanisms, such as cyclone dust collectors and condensate scrubbers, are incorporated to meet air quality standards. This not only reduces volatile organic compound (VOC) emissions but also enables the recovery of wood vinegar and tar for secondary applications.

Industrial Adoption and Policy Alignment

Biochar’s role as a renewable fuel aligns with global directives aimed at decarbonizing energy systems. Manufacturing plants in sectors such as cement, ceramics, and metallurgy have begun integrating biochar as a partial coal substitute, attracted by its consistent combustion characteristics and low net emissions.

Governments are increasingly supporting the deployment of carbonization machine through green financing, carbon offset programs, and rural development initiatives. These measures create a favorable ecosystem for scalable biochar energy production.

Conclusion

Biochar, once confined to soil enhancement, is now emerging as a renewable solid fuel with broad industrial relevance. Advanced systems—ranging from the rice husk charcoal making machine to the palm kernel shell charcoal machine—demonstrate the adaptability of modern carbonization technology. As demand grows for decentralized and sustainable fuels, biochar’s thermal and environmental performance offers a compelling alternative within the evolving energy landscape.