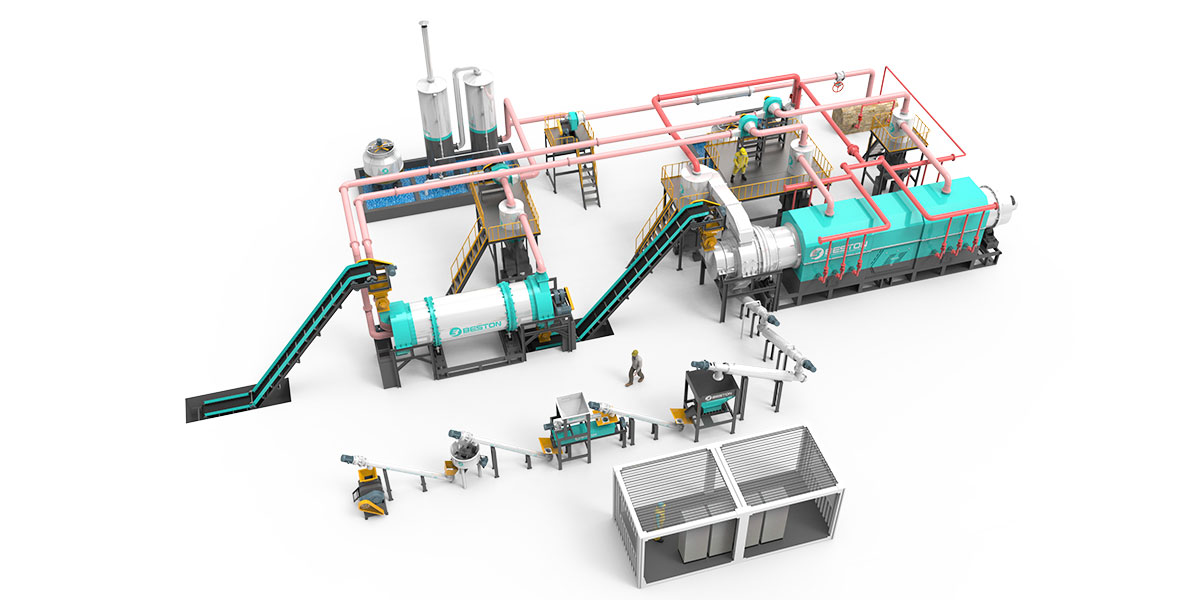

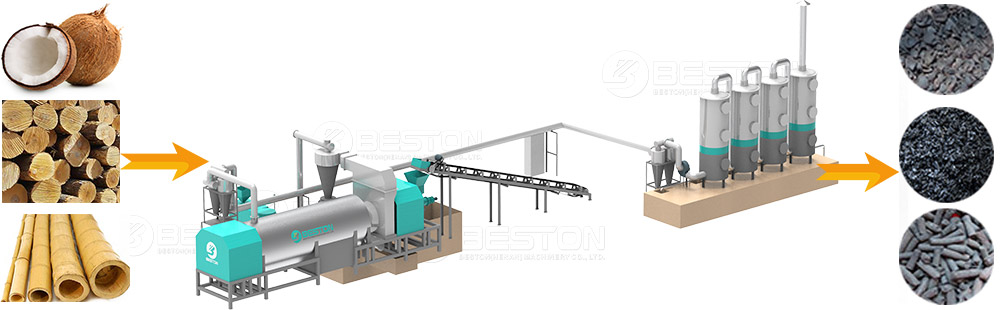

The biomass carbonization machine also known as the biomass charcoal machine or biomass pyrolysis plant uses a specialized waste-treatment technology that disposes of many types of different biomass waste. Examples of this waste include wood, wood chips, rice husk, plant matter, coconut shells, sewage sludge, palm shells, and more.

Carbonization references a process that uses biomass carbonization machine at a high temperature. The process produces carbon enrichment, sulfur emissions, and volatile gas. Biomass carbonization produces charcoal along with other by-products such as fuel oil, tar, and wood vinegar.

BST-10 Wood Chips Biomass Pyrolysis Plant In China

Application Fields:

– Forestry and Agricultural

Forestry and agricultural waste such as coconut shells, sawdust, rice husk, wood, plant stalks, vines, and other types of biomass materials.

– Municipal Waste Treatment

Municipal sludge and solid waste treatment.

– Industrial Paper-making Sector

Treatment plant for paper-producing waste

– Soil Improvement

Along with other industrial sectors

What Is The Process Of Biomass Carbonization

• The crushed biomass materials are fed into a silo with the use of a forklift

• The materials are then fed into a feeder via a conveyor belt and then into a carbonization furnace of coconut shell charcoal making machine.

• The pyrolysis process generates combustible gas which then enters a cyclone before entering a condensation-analyzer system. The gas is then purified in the dust collector.

• The exhaust gas is then used to supply fuel to the drying system.

• This process also produces wood vinegar and tar which can be sold or stored as raw chemical materials

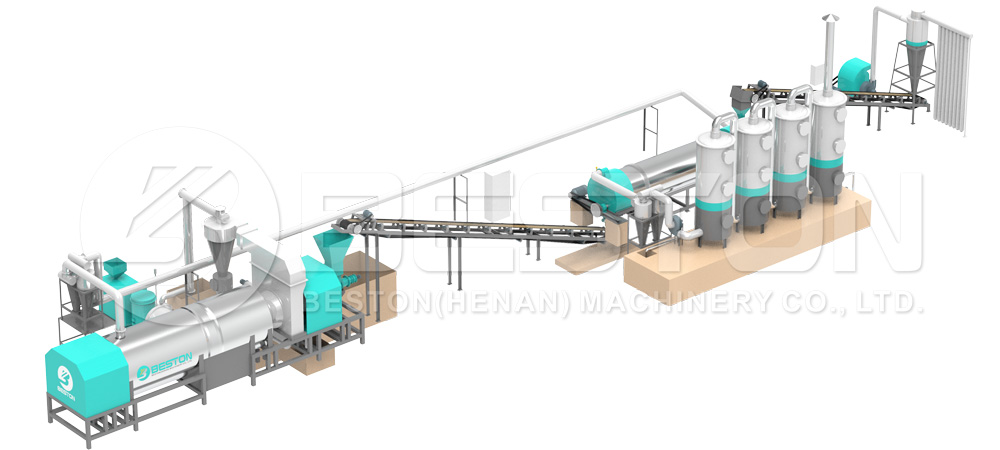

The Carbonizer Design

Biomass carbonization machines adopt a double-layer design with a multi-passage. These parts include a drier, the carbonizing machine or furnace, along with other important auxiliary equipment. There are also other parts such as the gasification furnace, wet-dust catcher, exhaust-gas recycling, feeding, discharging, and cooling parts.

The double-layer design in these machines is positioned at the bottom of the charcoal making machine for sale which ensures maximum contact with the heated air. This assists in raising the efficiency of heat utilization. This lower layer uses residual heat to flash steam and to carbonize the gas. This secondary stage raises heat utilization efficiency.

Sewage Sludge

The Biomass Carbonization Plant Offers The Following Benefits:

• The two-step fire method that is used by carbonization machines is exclusive. These machines make complete use of waste smoke and waste heat to lower the moisture content present in the biomass. The calorific fuel utilization rate has the potential to reach over 90%. Traditional machines do not feature this structure.

The carbonization machine can be fueled by a variety of different sources. Some of the common types include carbon, coal, gas, wood, etc. This is how carbonization machines help to reduce costs.

Among the many benefits of the carbonization machine, is the heat-resistant casing. This casing is a safety feature that helps to stop operators from getting burnt or scalded. This casing also serves another important function, and this includes heat preservation. These machines also come with an automated alarm system that activates once the thermometer or the pressure gauges has exceeded the standard numbers. Check the rice hull carbonizer here.