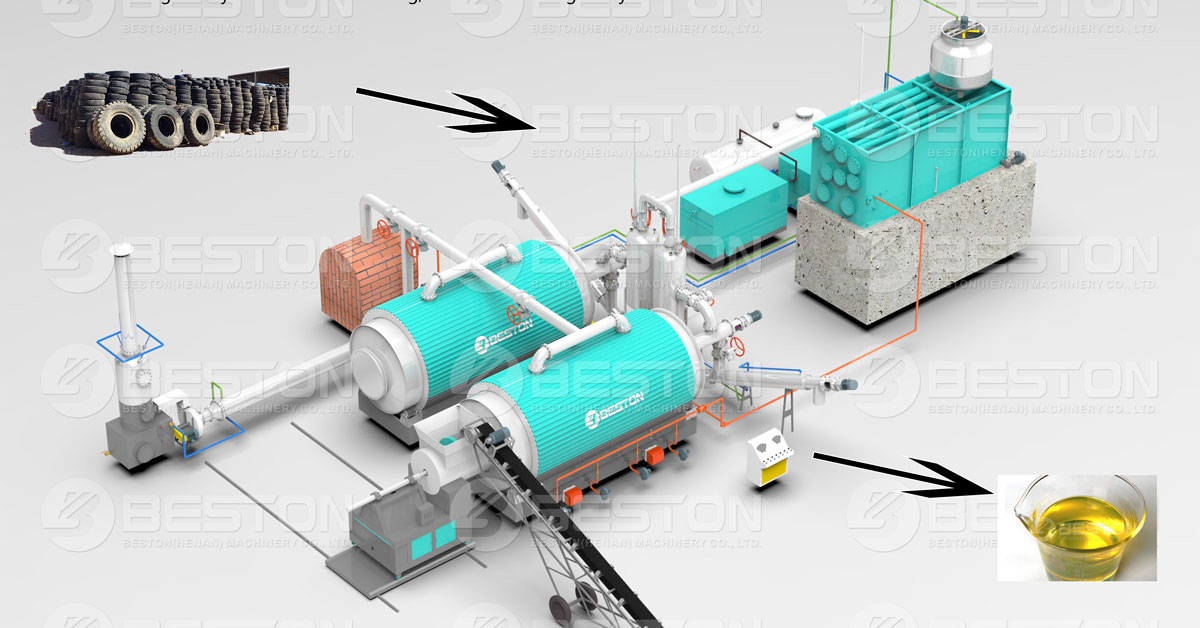

Pyrolysis, a process that converts waste materials into valuable products, has gained immense popularity in recent years due to its environmental benefits and resource recovery potential.

Beston Group, a leading manufacturer of pyrolysis plants, offers a range of advanced solutions. This article aims to provide a comprehensive analysis of the cost associated with Beston pyrolysis plants. By examining the initial investment, operational expenses, and return on investment, readers can gain valuable insights into the economic aspects of these plants.

I. Initial Investment Cost

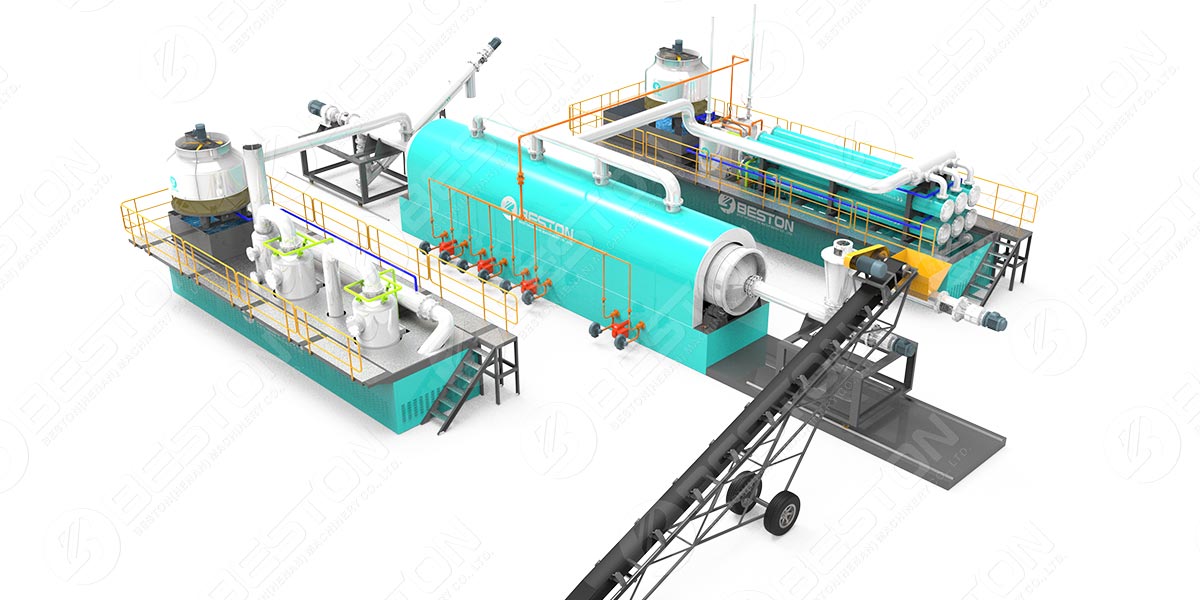

The initial investment cost for a pyrolysis plant for sale depends on several factors, including plant capacity, technology used, and additional equipment required. The capacity of Beston pyrolysis plants ranges from small-scale to large-scale, catering to different waste volumes. The cost per unit capacity generally decreases with an increase in plant size, owing to economies of scale. Moreover, the technology used in the plant, such as the reactor design and heating system, affects the overall cost.

In addition to the core pyrolysis unit, auxiliary equipment like shredders, conveyor belts, and waste pre-treatment systems may be necessary. These additional components contribute to the overall investment cost. It is crucial to consider the quality and durability of the equipment to ensure long-term reliability and operational efficiency. Beston’s reputation for providing high-quality machinery justifies the initial investment, as it ensures a robust and reliable pyrolysis plant.

II. Operational Expenses

Apart from the initial investment, operational expenses play a vital role in assessing the overall cost of a pyrolysis plant. Several factors influence operational expenses, including raw material cost, labor, energy consumption, maintenance, and waste disposal.

The raw material cost is a significant expense for a pyrolysis plant. The type and availability of waste materials in a particular region affect the cost. Beston pyrolysis plants are designed to handle a wide range of waste, such as plastic, rubber, biomass, and municipal solid waste. The versatility in waste selection allows for flexibility and potential cost optimization.

Labor cost is another operational expense to consider. Beston’s pyrolysis plants are designed with automated systems and advanced control panels, minimizing the need for extensive manual labor. This reduces labor costs and ensures safe and efficient plant operations.

Energy consumption is a significant expense in pyrolysis plant cost operations. Beston utilizes advanced heating systems, such as direct heating and indirect heating methods, which optimize energy efficiency and reduce operational costs. Additionally, integrating energy recovery systems can further reduce energy consumption and improve overall plant economics.

Regular maintenance is essential to ensure optimal performance and longevity of the plant. Beston provides comprehensive after-sales support, including maintenance training, spare parts availability, and technical assistance, which contribute to reducing maintenance costs over time.

Proper waste disposal is crucial to comply with environmental regulations. Beston pyrolysis plants are equipped with advanced emission control systems, such as scrubbers and filters, to minimize emissions. Compliance with regulations not only avoids penalties but also contributes to maintaining a positive reputation and sustainable operations.

III. Return on Investment

Assessing the return on investment (ROI) is essential for pyrolysis plant project report. The ROI depends on various factors, including the market demand for the end products, the selling price of the products, and the operational efficiency of the plant.

Beston pyrolysis plants produce valuable end products such as pyrolysis oil, carbon black, and combustible gas. The market demand and prices for these products vary depending on factors such as regional demand, government policies, and environmental consciousness. Conducting market research and identifying potential buyers or industries that require these products is crucial to estimating the ROI accurately.

The operational efficiency of a Beston pyrolysis plant, coupled with its product quality, influences the ROI. Efficient plant operations result in higher production volumes and lower operational costs, ultimately enhancing profitability.

Moreover, the scalability of Beston pyrolysis plants allows for potential expansion or diversification, further contributing to ROI. As the demand for sustainable waste management solutions continues to grow, investing in a Beston pyrolysis plant presents an opportunity for long-term profitability.