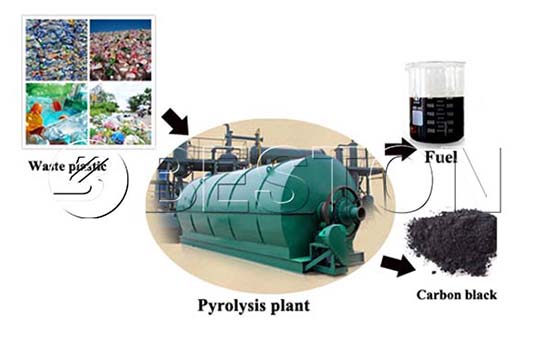

In the face of mounting environmental challenges, pyrolysis has emerged as a revolutionary technology capable of addressing waste management issues worldwide. From plastics to tires and biomass, pyrolysis offers a sustainable and efficient solution for converting waste into valuable resources.

Why Pyrolysis Projects Are Thriving Globally

The widespread adoption of pyrolysis technology can be attributed to several key factors:

1. Environmental Necessity

The growing waste crisis has pushed governments and industries to seek sustainable solutions. Pyrolysis offers an environmentally friendly method for managing waste such as plastics, tires, and biomass. By converting waste into reusable resources like fuel oil, syngas, and biochar, pyrolysis helps reduce landfill dependency and minimizes greenhouse gas emissions.

2. Technological Advancements

Modern pyrolysis reactor has become more efficient and cost-effective, enabling scalability and reducing operational costs. Innovations in design and automation ensure consistent performance, making it easier for countries to adopt this technology.

3. Versatile Applications

Pyrolysis is not limited to a single type of waste. Its versatility allows it to process various feedstocks, including:

- Plastics: Non-recyclable plastics are transformed into fuel oil and syngas.

- Tires: End-of-life tires are converted into carbon black, steel wire, and tire-derived oil.

- Biomass: Agricultural and forestry residues are processed into biochar.

This adaptability makes pyrolysis an attractive solution for regions with diverse waste streams.

4. Economic Incentives

The economic benefits of pyrolysis are significant. By creating valuable byproducts, such as renewable energy sources and raw materials, pyrolysis plants contribute to local economies. Additionally, the technology supports circular economy principles by turning waste into resources, reducing reliance on virgin materials.

5. Global Collaboration

International cooperation and knowledge-sharing have accelerated the adoption of pyrolysis technology. Companies like Beston Group are leading the way, providing customized solutions for various regions and fostering partnerships to address local waste management challenges.

Regions Supporting Pyrolysis Projects

Countries worldwide are recognizing the potential of pyrolysis to tackle waste management and promote sustainability. Here are some key regions that are actively supporting the establishment of pyrolysis plants:

1. Europe: A Pioneer in Waste-to-Energy Solutions

European countries, known for their stringent environmental regulations, are at the forefront of adopting pyrolysis plant in Europe. Nations like Germany, the Netherlands, and the UK are investing in advanced pyrolysis reactors to process plastic and tire waste. Key drivers in Europe include:

- Policy Frameworks: EU directives on waste reduction and recycling have created a strong demand for innovative solutions like pyrolysis.

- Research and Development: Europe’s focus on R&D ensures continuous improvements in pyrolysis technology, making it more efficient and accessible.

- Public Awareness: High levels of environmental awareness among European citizens drive support for sustainable waste management initiatives.

2. Turkey: A Hub for Pyrolysis Innovation

Turkey has emerged as a leading supporter of pyrolysis technology, driven by its commitment to reducing plastic waste and achieving environmental goals. The establishment of a pyrolysis plant in Turkey reflects the country’s proactive approach to sustainable waste management. Key drivers in Turkey include:

- Government Initiatives: Turkey has implemented strict regulations to reduce plastic pollution and encourage recycling. These policies create a favorable environment for pyrolysis projects.

- Industrial Demand: The byproducts of pyrolysis, such as fuel oil and carbon black, are in high demand across various industries, including energy and manufacturing.

- Geographical Advantage: Turkey’s strategic location between Europe and Asia makes it a hub for international trade and collaboration, facilitating the export of pyrolysis byproducts.

The success of the pyrolysis plant in Turkey serves as a model for other countries seeking to adopt similar solutions.

3. Asia-Pacific: A Growing Market for Pyrolysis

Countries in the Asia-Pacific region, including Malaysia, India, China, and Indonesia, are rapidly adopting pyrolysis technology to tackle their growing waste problems. Malaysia is a region that has embraced pyrolysis technology, particularly for managing plastic and biomass waste. The establishment of a pyrolysis plant in Malaysia highlights the country’s dedication to sustainable development. Key drivers in Europe include:

- Abundant Feedstock: Malaysia generates significant amounts of plastic waste and agricultural residues, providing ample raw materials for pyrolysis.

- Government Support: Policies promoting renewable energy and waste-to-resource initiatives have paved the way for pyrolysis projects.

- Private Sector Involvement: Companies in Malaysia are investing in pyrolysis technology to reduce waste and create economic opportunities.

The pyrolysis plant in Malaysia showcases how the technology can address local waste challenges while contributing to global sustainability efforts.

The Role of Pyrolysis Reactors

At the heart of every pyrolysis plant is the pyrolysis reactor, a crucial component that determines the efficiency and output of the process. Modern reactors are designed to:

- Maximize Yield: Advanced designs ensure the highest possible conversion rates for feedstock.

- Enhance Safety: Features such as temperature control and automated systems minimize risks.

- Reduce Emissions: Innovative technologies capture and reuse gases, making the process environmentally friendly.

The spread of pyrolysis technology worldwide reflects its effectiveness in transforming waste into valuable resources while addressing critical environmental challenges. Regions like Turkey and Malaysia are leading the way, showcasing how pyrolysis can be tailored to local needs and opportunities.

With advancements in pyrolysis reactors and increasing global collaboration, pyrolysis is poised to become a cornerstone of sustainable development. By embracing this innovative technology, countries can turn waste into wealth and pave the way for a greener, cleaner future.