Oil sludge is an inevitable byproduct of the oil refining process, characterized by a mixture of oil, water, solids, and other contaminants. Its disposal poses significant environmental challenges due to its hazardous nature and potential for soil and water contamination. To manage oil sludge effectively, various methods and technologies have been developed.

Oil Sludge Pyrolysis Solution

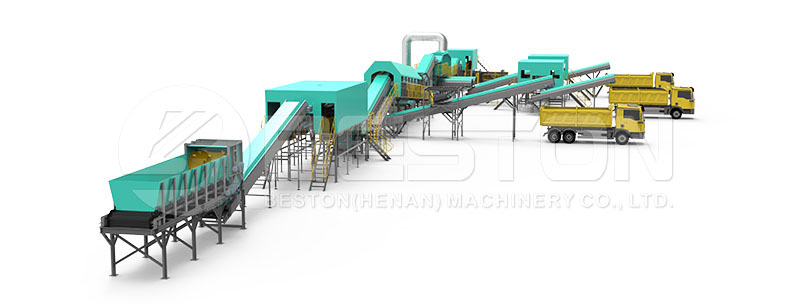

Oil sludge pyrolysis plant is an innovative and eco-friendly method that addresses the disposal challenges posed by this hazardous waste material. It involves subjecting oil sludge to high temperatures in an oxygen-deprived environment, initiating a thermal decomposition process known as pyrolysis.

During oil sludge pyrolysis, the complex organic compounds present in the sludge undergo thermal degradation, breaking down into smaller hydrocarbons, gases, and solid residues. This process effectively converts the organic components of oil sludge into valuable products.

The primary product obtained from oil sludge pyrolysis is pyrolysis oil, a dark-colored liquid rich in hydrocarbons.

Oil Sludge Pyrolysis Treatment

Bioremediation: Harnessing Nature’s Cleaning Power

One promising method for treating oil sludge is bioremediation. This process utilizes specialized microorganisms to break down hydrocarbons in the oil sludge into less harmful byproducts. These microorganisms thrive in oxygen-rich environments and can be introduced to the sludge along with necessary nutrients and proper environmental conditions to facilitate the decomposition process. The Beston Group can provide eco-friendly solutions. Welcome to click.

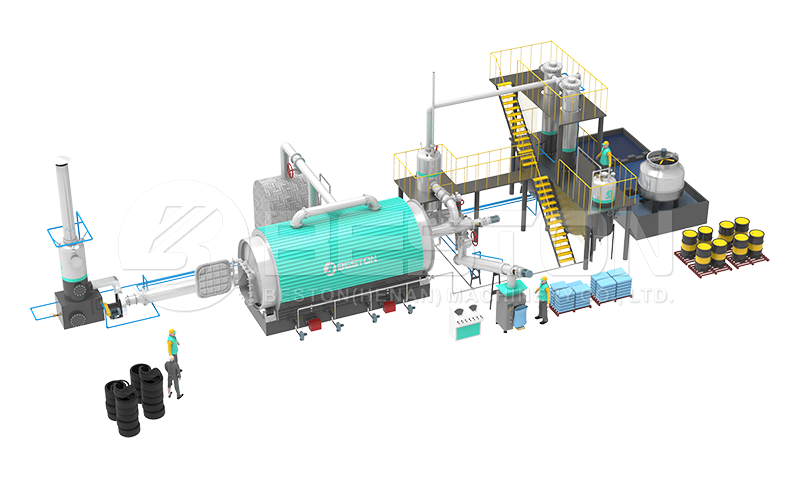

Thermal Treatment: High-Temperature Solutions

Thermal treatment involves subjecting the oil sludge to high temperatures in specialized incinerators or thermal desorption units. This method thermally breaks down the sludge components, reducing it to ash, gases, and residual solids. It’s an effective way to minimize the volume of oil sludge and destroy hazardous contaminants, but it requires sophisticated equipment and careful monitoring to control emissions.

Chemical Solvents: Dissolving the Challenge

Chemical solvents offer another approach to manage oil sludge. Utilizing specific chemicals or surfactants, this method aims to dissolve the hydrocarbons present in the sludge, separating them from the solid components. While effective, this process demands careful handling of chemicals and the subsequent treatment of the separated components.

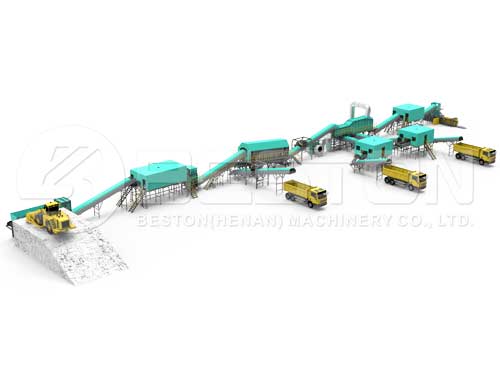

Mechanical Separation: Segregating Components

Mechanical separation involves using various physical methods like centrifugation, filtration, and sedimentation to separate the different components of oil sludge. This method targets the removal of water, solids, and oil fractions, enabling the recovery of usable oil and facilitating the treatment and disposal of the remaining components. Get pyrolysis plant cost here.

Landfarming: Facilitating Natural Degradation

Landfarming, or land treatment, involves spreading oil sludge over designated areas and systematically turning and aerating it to encourage microbial degradation. By providing ideal conditions such as moisture, oxygen, and nutrients, the natural microbial activity breaks down the hydrocarbons, gradually reducing the sludge’s hazardous properties.

Secure Disposal and Regulations

Regardless of the chosen disposal method, adhering to stringent environmental regulations is paramount. Many jurisdictions have specific guidelines and regulations governing the handling, treatment, and disposal of hazardous waste like oil sludge. Compliance with these regulations ensures safe and responsible handling while minimizing environmental impact.

Future Prospects and Innovations

Continual research and innovation in waste management technologies offer promising prospects for more efficient and sustainable oil sludge disposal. Advancements in bioremediation techniques, the development of eco-friendly solvents, and improved thermal treatment methods aim to enhance efficiency while minimizing environmental consequences.

Conclusion

The management and disposal of oil sludge demand careful consideration and adherence to environmentally conscious practices. Employing a combination of bioremediation, thermal treatment, chemical solvents, mechanical separation, and landfarming can address the complexities of oil sludge disposal while mitigating environmental hazards. Striving for innovation and compliance with regulations remains crucial in achieving responsible and sustainable handling of oil sludge for a cleaner and healthier environment. Check the waste tyre pyrolysis plant here.