Waste plastic is a major and growing problem in South Africa and the world over. 2016 saw over 1.14 million tons of plastic, which could be recycled, join the waste management system of South Africa. Almost 42% of this plastic was recycled, but this shows there is still a need for more recycling. One way to deal with this problem is to turn the plastic waste into oil. There are many benefits for businesses to look for a plastic to oil machine for sale in South Africa, in order to improve these recycling numbers further.

How Does A Plastic to Oil Machine Work?

1. There is some water contained in waste plastic and this needs to be removed. Oil and water don’t mix as the molecules contained in the water are attracted to each other more than the oil molecules. The way this is dealt with in the plastic to fuel machine is to steam the water out in a dryer.

2. Larger plastic pieces need to be reduced in size for the machine to be able to process the waste. The machine can have a crusher added to deal with this issue.

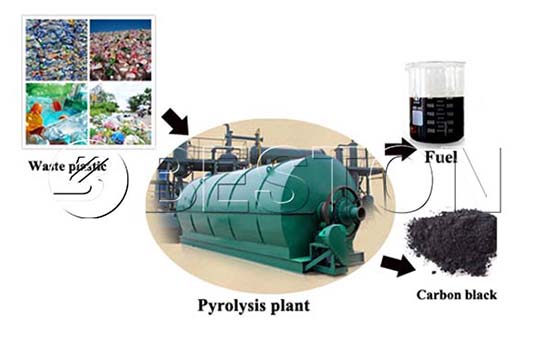

3. To convert the plastic into oil a plastic pyrolysis reactor is used. A pyrolysis reactor is an efficient way to increase the yield and reduce operating costs. The way it works is by using a high temperature and pressure vacuum. Temperatures can reach 350 degrees Celsius and the process can take up to 10 hours. During this process, combustible gas is released, carbon black and oil gas are created. Once this process is complete a couple of hours are needed for cooling to increase the oil yield.

4. The automatic discharging system will then move the substances on in the process. A manifold is used to separate out the different substances – gas oil, light oil and heavy particles. Here is a video of continuous waste plastic pyrolysis plant from Beston Machinery for your reference.

5. An oil condenser is then used to reduce the heat in the oil gas enabling it to be liquefied.

6. In order to improve the purity and increase the safe operation of the system, a hydroseal is used. The hydroseal removes the sulfur from the combustible gas. This can then be used to provide additional heat to the system, creating a fuel saving. This feature makes your plastic recycling machine price in South Africa more affordable.

7. The smoke created in the reactor is piped through a heat exchange system, which enables hot air to be added back into the heating system. The smoke is cooled down further, dust particles being removed through washing and via adsorption in carbon and ceramic chambers. The smoke then leaves the system after moving through more filters to conform to EU emission standards.

Products of Plastic to Oil Machine

The pyrolysis machine produces three products from the plastic recycling process:

Oil – the oil produced can be processed into either diesel or gasoline.

Combustible Gas – this can be sold for other industrial uses or be used to heat the reactor.

Carbon Black – this has many uses in industry, including being used in tire construction, as a mixer in plastic and in copier or printer toner.

The various end products make plastic recycling profitable so that more investors try to invest in a top quality plastic pyrolysis plant. The important thing is to get a fair plastic pyrolysis plant cost in South Africa.

End Products of Plastic to Oil Machine

Advantages of Turning Plastic to Oil in South Africa

As you can see the benefits of a business looking for a plastic to oil machine for sale South Africa can be great. Not only are you helping reduce the waste plastic problem South Africa faces, but you can turn this back into products that will help the economy too. More information about plastic recycling machines in South Africa can be provided professional advice from Beston Machinery.